PHOENIX – Miracle Mile Deli has been proudly serving pastrami sandwiches for 72 years, but the pandemic has Josh Garcia’s restaurant in “survival mode.”

“What we’re seeing is the normal products that we’ve been able to get ahold of easily, like chicken tenders, we can’t get ahold of,” Garcia said. “The manufacturers are experiencing staffing issues like we are, but now that the world is open, they can’t keep up with the demand, so they’re trying to recover and we’re on the receiving end of it.”

Small businesses and restaurants across metro Phoenix are struggling to stay afloat because of supply chain shortages and price hikes as they compete with Walmart, Amazon and other powerhouses for products to fill shelves and pantries. They also compete for workers to fill essential staffing positions.

Garcia touts Miracle Mile as one of the biggest pastrami users on the West Coast; the restaurant serves about 3,000 pounds of pastrami each month. But the price, he said, has gone up $2 per pound since the pandemic was declared in March 2020.

“We’ve taken a 30% price increase on products across the board since COVID started, so whether it’s disposables, food or drinks, everyone has encountered some form of price increase,” he said. “All of the big stores have a lot of money and backing with investors and customers, but we’re just a small mom-and-pop business that’s been around for 72 years with 24 employees.”

Wells Fargo senior economist Mark Vitner said the $5.2 trillion in stimulus checks issued in 2020 and ’21 helped revive consumer spending more quickly than supply, which shut down when demand plummeted at the beginning of the pandemic.

“We basically drew down inventories of just about everything, and production has been trying to catch up,” Vitner said. “We still haven’t recovered all the jobs that were lost during the pandemic, and factories and warehouses are having a hard time attracting workers back.”

Vitner said he expects supply chain worries are at their peak, with prices going up by 7.1% in Phoenix from a year ago, according to October Consumer Price Index data.

“I think we have seen some modest incremental improvement in just the last few weeks,” he said. “And I think that six months from now we’ll be in a better place, but we’re not going to get completely past these supply chain issues for at least a year.”

Although restaurants aren’t as affected by supply chain problems and shipping issues as much as other industries, such as construction and homebuilding, small businesses don’t have the bargaining power when it comes to keeping restaurants open without exhausting staff, Vintner said.

“Some chains are even closing underperforming stores while some are converting to ghost kitchens that serve the delivery market,” he said. “It’s a real tough environment to operate in.”

Searching for supplies

Chip Mahoney, owner of Wicked Brews, Bites & Spirits in the Ahwatukee Foothills section of Phoenix, hasn’t had enough silverware since September. Normally, silverware is washed and folded into cloth napkins at the end of worker shifts but, instead, he spends his days driving to shops and supply stores hoping to find silverware and other supplies for the restaurant while staff washes and folds even during busy hours.

“I’m driving around getting nowhere and wasting my day,” he said. “That’s not how I want to run my business – driving around the Valley looking for products that I need to run my business.”

Wicked Brews celebrated its first anniversary in November, first opening its doors when pandemic dining restrictions limited what the restaurant could do for the first four months. Mahoney said he and his employees worked to promote the new restaurant while adhering to COVID-19 protocols, such as reduced seating and closing a few days a week.

“It was starting to get better until the supply chain and lack of employee interest, which has really been a damper over the past four months,” Mahoney said. “That’s actually harder than when we first opened.”

Wicked Brews opened in November 2020 and has worked with COVID-19 dining protocols to stay in business. The owners also added live music two nights a week. (Photo courtesy of Wicked Brews)

Mahoney said it’s a numbers game, from trying to make sure Wicked Brews is stocked with products for the dining room while still trying to keep prices low to keep and attract customers. But even with product price increases that have led to higher menu prices, the bills are still stacking up.

The alcohol industry is also being affected by shipping and other supply chain issues, with many breweries and distilleries struggling to find supplies to bottle their booze.

Brothers Josh and Jason Duren, who co-own Cider Corps in Mesa, have been laboring to get apple juice and fruits to brew their ciders, but they also have had a hard time finding cans for said ciders.

Wendy Tilton from Wild Hare Distillery in Tempe said her issue isn’t finding bottles to put their alcohol in, but finding the same style of bottle to continue brand consistency.

“Our last order was supposed to come in August, and I still don’t have it yet,” she said in late November. “We ordered 375-milliliter bottles earlier this year and waited for months to get them. And once they did come in, the bottle company could not find corks or sleeves to seal it.”

The struggle to staff

Mahoney said another part of his day-to-day routine is finding employees to work in the restaurant. As a mom-and-pop operation, he said the business doesn’t have enough money to pay for the number of people needed to properly staff the restaurant.

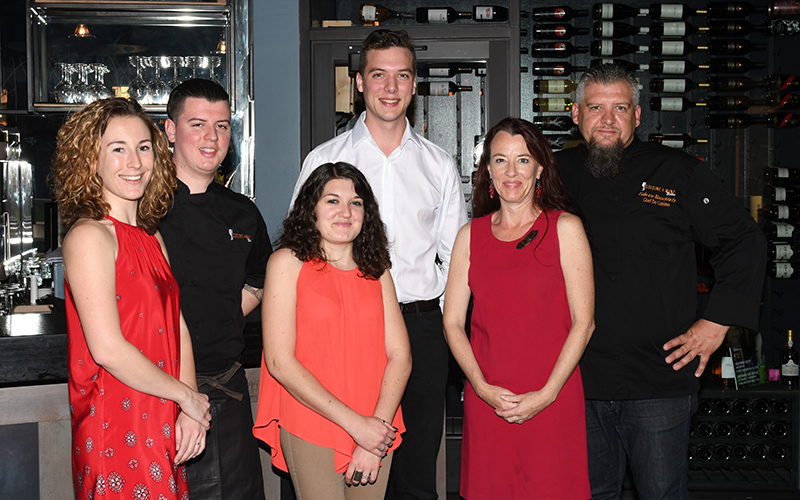

The Buschtetz family – from left, Clementine, Steven, Laura, Killian, Mairead and Fabrice – owns multiple restaurants across the Valley, including Cuisine & Wine Bistro, B Gastrobar and Frenchie Pizza. (Photo courtesy of Buschtetz family)

Mairead Buschtetz and her husband, Fabrice, are also struggling to find workers for their multiple restaurants and bistros across the Valley, including Cuisine & Wine Bistro in Chandler and Copper & Logs in Gilbert.

It feels like they’re in a “vicious circle,” Mairead Buschtetz said.

“We got great federal help last year to stay open, and we were very blessed, but this year, there’s no federal help left,” she said.

Normally, Buschtetz said, five people work in the Cuisine & Wine Bistro kitchen at a time: Her husband, the executive chef of all the family’s restaurants, works with three other cooks and a dishwasher. Right now, however, Fabrice is the only cook and there is no dishwasher.

Instead, the Buschtetzes and their three children have been filling in where they can to keep the restaurants going with Frenchie Pizza in Gilbert facing the most challenges with staffing.

Even though she needs to hire workers, Mairead said she can’t afford to pay them because of increasing costs elsewhere in the business. Even with wages ranging from $13 to $23 per hour, Mairead said, the family can’t compete with companies like Amazon and Whole Foods.

“Our rent is more expensive by at least $1,000, and the case for the payroll costs are huge with our products coming in at least 30% more expensive than usual,” she said. “It’s a terrible situation to be in, and I can’t see a light at the end of the tunnel. I don’t know how long people are going to be able to hang in there.”

Working together

Many restaurants have had to get creative by either changing restaurant concepts or adding partnered experiences to continue attracting customers and make up for some of the shortages. Josh Duren of Cider Corps said these challenges have created a “forced level of creativity” that, in the end, could benefit American small businesses.

“It’s built a really strong kind of bond where people realize that to survive, you have got to rely on other people for help,” he said.

Wild Hare partnered with a local chocolate company, Stone Grindz in Scottsdale, to create a tasting event catered by a chocolatier who paired different chocolates with their spirits, and Tilton said they will continue for the holiday season; by reservation only on Fridays, Saturdays and some Sundays.

At Wicked Brews, live music wasn’t something Mahoney intended to provide, but since introducing it during the pandemic, it has become a regular thing Wednesday and Friday evenings.

“You have to adjust your business plan, know your market and your guests to just stay on top,” he said. “Every penny counts right now.”