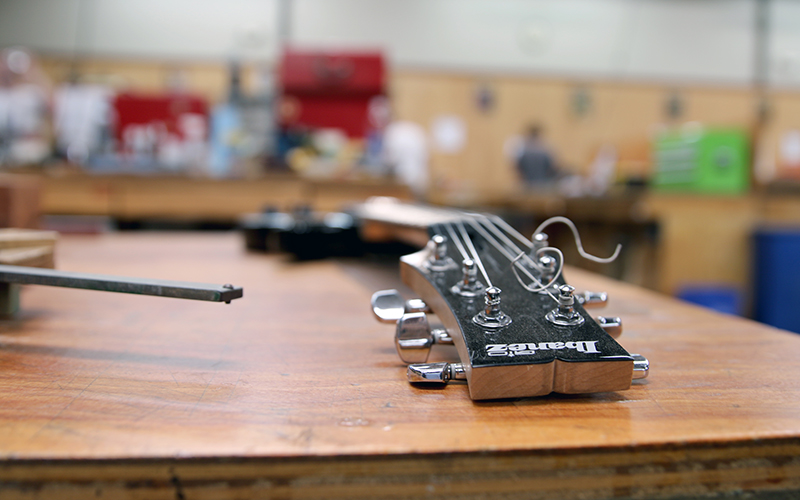

An electric guitar worked on by Roberto-Venn School of Luthiery students on Thursday, Sept. 15. Students focus on crafting one acoustic and one electric guitar before graduating. (Photo by Joshua Bowling/Cronkite News)

PHOENIX — Buzz saws, sanders and wood clacking on wood crescendo above 40 students’ competing conversations as they craft acoustic and electric guitars.

For every chord progression a guitarist plays on stage, for every arpeggio an amateur musician plucks in a garage band, students fashion a corresponding rough, unfinished slab of wood into something greater.

The Roberto-Venn School of Luthiery teaches students how to embrace music at its genesis, making musical instruments inside a bland, wrought iron-fenced building in central Phoenix.

A long journey to musical passion

James Choi, a 32-year-old student at Roberto-Venn, had languished for years in a series of mundane jobs before he left New Jersey to start his formal luthiery education in August.

Until then, Choi had tried a little bit of everything. He worked in metal recycling, project planning and services for people with mental disabilities. Along the way, about a decade ago, he considered enrolling at the Phoenix school but couldn’t afford it. He most recently spent time in IT and considered settling in that career.

“IT got a little bit tiresome, so I was looking into jumping into another company or doing something else,” he said. “I came across an old student from here … and I mentioned it to my wife, and she’s like, ‘I think you should do it.'”

Choi tried it out first, taking a one-week, intensive guitar-making course with a Pennsylvania-based luthier. He loved it. In his first weeks in Phoenix, he’s found the passion that eluded him all this time. He plans to eventually open a guitar store.

“For someone like myself, who has been through multiple career changes and is looking to get into it as fast as possible … it’s an incredible opportunity,” he said. “Ten years later and four career changes later, I made my way with the support of my wife who sent me out here. I get to fulfill my dream now.”

Students build guitars at work stations. The school teaches a craft that fashions guitars from a block of wood to instruments for stage, school auditoriums or homes. (Photo by Joshua Bowling/Cronkite News)

Composing community, hour after hour

Students clock long hours while studying and crafting guitars but come away with something tangible — something musical.

Choi said the school fosters a sense of community, allowing him to bond with his classmates over a common interest.

“We spend 10 hours a day, if not more, together,” he said. “You definitely get to know a lot of people rather quickly.”

Music doesn’t always accompany the instruments.

Visitors who walk through the school’s nondescript front doors near Grand and 10th avenues encounter a wall of guitars on display, their riffs and rhythms quieted. The silence of the showroom gives way, just out of visitors’ sight, to a workshop where students turn wood and strings into vessels of music.

The school has been an accredited trade school since 1975 and has trained thousands of students to make and repair guitars, according to Barton Applewhite, assistant director. Luthiery is derived from the art of manufacturing lutes — the musical predecessor to the guitar.

Applewhite said he’s been working with music in one way or another for most of his life, but didn’t set out with a specific business plan in mind when he decided to turn music into a living.

“I played music in high school and then somehow had the idea that I was going to make my own instruments,” Applewhite said. “I don’t know where that wild idea came from, and then it kind of stuck.”

Applewhite enrolled in Roberto-Venn in 1990. After he graduated, he pursued his career for more than a decade before returning in 1991 to manage the school.

‘Not a Fortune 500 career’

Applewhite said the school draws people who are passionate about music and want to pursue the art at its origin: the construction of an instrument.

“This is a legitimate career, (but) it’s not a Fortune 500 career,” he said. “It’s more of a lifestyle career where people want to be excited on Monday morning when they wake up. A lot of our grads are among the top guitar makers in the world.”

Applewhite said students clock in 880 hours, about nine hours per day, before they complete the five-month program. Tuition is $10,950, but total costs runs closer to $14,000 once students have all the supplies they need, he said.

Students learn how to put together a guitar in a classroom before they put their hands to work. Once they do, they sand the piece of wood down and rough out its edges. Later, the guitar’s six strings are put in, one of the last steps before notes will be ready to cascade out of an instrument.

John Reuter, the school’s director of training, manages the curriculum. He said the school draws students from numerous walks of life who are serious about learning the craft.

“I was a woodworker when I was a kid and got a degree in manufacturing engineering. When I graduated, I didn’t want to build bombs,” Reuter said. “I found out there was a guitar-making school in town and I was signed up the next day.”

An Arizona State University graduate, Reuter said woodworking ran in his family, who taught him how to frame houses. Once he enrolled in luthiery school, he realized he could apply that knowledge outside of a traditional construction career.

“Back then, it was a four-month program and they never got rid of me, so I couldn’t leave,” Reuter said. “And I’ve been here 32 years.”

His advice to others: imagine a once inconceivable future.

“The two things I always told people I would never be was a musician or a teacher,” Reuter said. “And now, that’s all I do.”